RF-HSS performs the ultimate limit state design according to the requirements of the following standard. The types of connections are.

Welded Truss Connections Between Hss Branches And I Shaped Chords Steel Tube Institute

And if the bolted connection is inevitable then the fewer bolts the better.

. The design wall thickness t shall be taken equal to 093 times the nominal wall thickness for electric-resistance-welded ERW HSS and equal to the nominal thickness for submerged-arc-welded SAW HSS ERW HSS produced to ASTM A500 and A53. DESIGN OF WELDED CONNECTIONS AWS D112000 2423 Minimum Length. These design tools are now available through the Steel Tube Institute under Products Resources Design Aids.

As a sequel this paper discusses the special. Figure 5-1c depicts a typical field-welded HSS to gusset plate connection. QuickQnect - Connection Design.

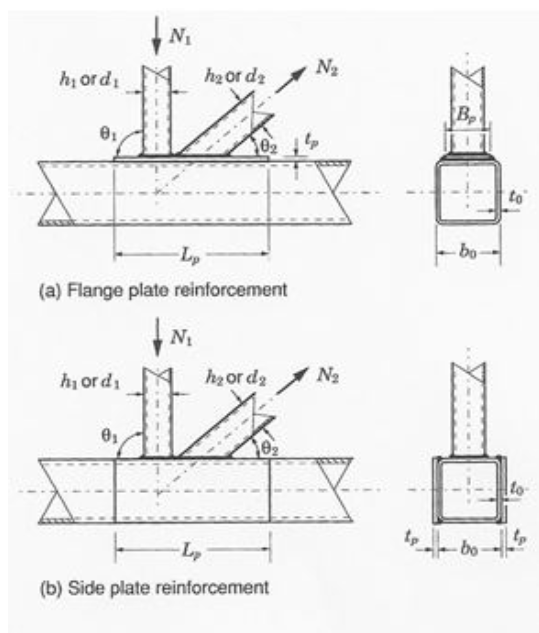

To attach the end plate to the HSS. Details of the two methods can be found in an earlier technical paper Welding of Hollow Structural Sections. In an effort to reduce the inherent flexibility of longitudinal branch plate connections stiffening plates or structural tees are sometimes welded to the HSS connecting face.

The directly welded moment connection is the weakest connection amongst all the connection but it is also the most commonly used of the moment connections in light weight frames. Hss Welded Connection Design. This specification never appeared in the Manual of Steel Construction but it did appear in the HSS Connections Manual.

ΦR n 10BtF ytb f F yp tfbf ΦR n 584 k 51 k OK 11 Directly Welded Connection Example HSS shear yieldingpunching Applicable when. K with two or three branches in a. Hss welded connection design Sometimes you would like an primary and simultaneously an easy nail design.

Therefore this needs to be. Our speed helps you stick to the schedule. SkyCiv Connection Design can design the following HSS to W shape connections under AISC and Eurocode Design Standards.

T or Y with a single branch perpen-dicular or at an angle to the main member. 085B b f B-2t. The weld can be proportioned so that it develops the yield strength of the connected.

Hollow structural sections HSS. A conventional longitudinal branch plate-to-HSS member connection tends to cause excessive distortion or plastification of the HSS connecting face. RXCD produces calculations for over 100 projects a year and is continually expanding the number of licensed states.

It is possible to design planar and spatial truss nodes containing round square or rectangular hollow sections. AISC Connections Section NJ and AISC Manual Part 9 HSS and Box Member Connections Section NK Selecting Standard Connections from the AISC Manual AISC Manual Parts 9 10 Seismic Connection BMA Engineering Inc. Within minutes and often seconds your model will be connected to meet AISC requirements.

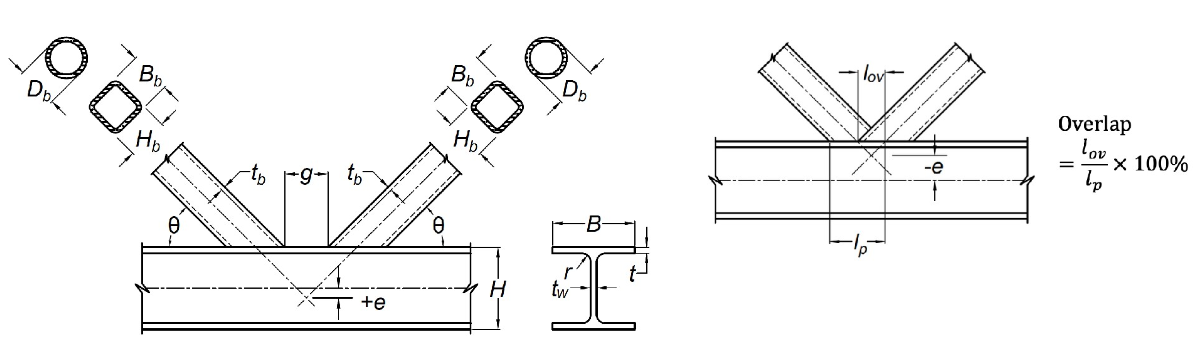

10112 HSSToHSS Truss Connections HSStoHSS truss connections are defined as connections that consist of one or more branch members that are directly welded to a continuous chord that passes through the connection and shall be classified as follows. Another useful publication is CIDECTs recent 9th design guide on connections. When you need to connect your model use QuickQnect.

Directly Welded Truss Connection K Connection TY Connection. Directly Welded Connection Example Check beam and HSS failure modes Transverse Plate connection AISC table K12. Another type of end connection is the slotted HSSgusset plate connection shown in Figure 5-1b.

RexConn Designs service area spans across North America including all 50 states and 5 Canadian territories. The optimal Resolution is definitely the designs with the nails with hearts. Spreadsheet tools that are available include the design of a WF Beam to HSS Column Shear Connection a WF Beam to HSS Column Moment Connection and an HSS to HSS truss connection.

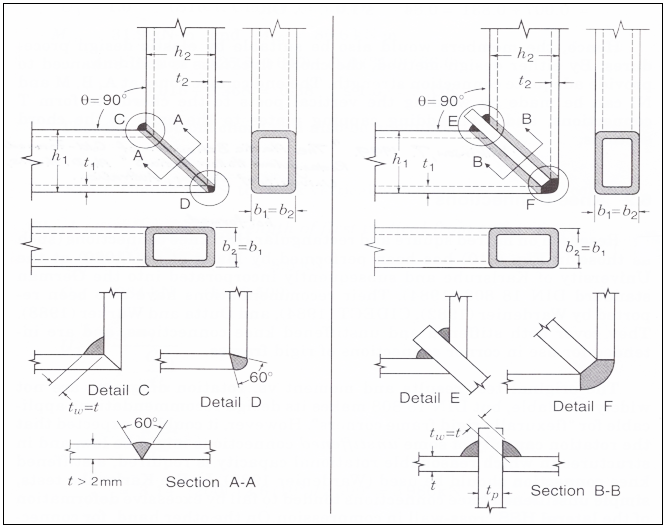

With HSS-to-HSS welded connections there are two design philosophies that can be used for weld design. Design A double WT connection is considered to be one of the cheaper alternatives to the Through Plate Connection and Collared Plate Connection as it only requires extra bolting or. The effective area shall be the ef-.

The RF-HSS addon module analyzes various hollow section connections or designs an existing connection. HSS Design with the Latest Codes. HSS to HSS Welded Connection - Side Matched Dimensions SwinnyGG Mechanical 10 Apr 18 2000 These welds are relatively easy compared to most welds with gaps because at each end where the weld would typically start there is a backer of sorts- the tube wall running away perpendicular to the weld.

The fewer connections visible the better. If the connection is needed then the welded one is desired more than the bolted one. Single Angle all bolted or all welded or weldedbolted Double Angle all bolted or all welded or weldedbolted Single Plate all welded or weldedbolted Single WT all welded or weldedbolted Through Plate.

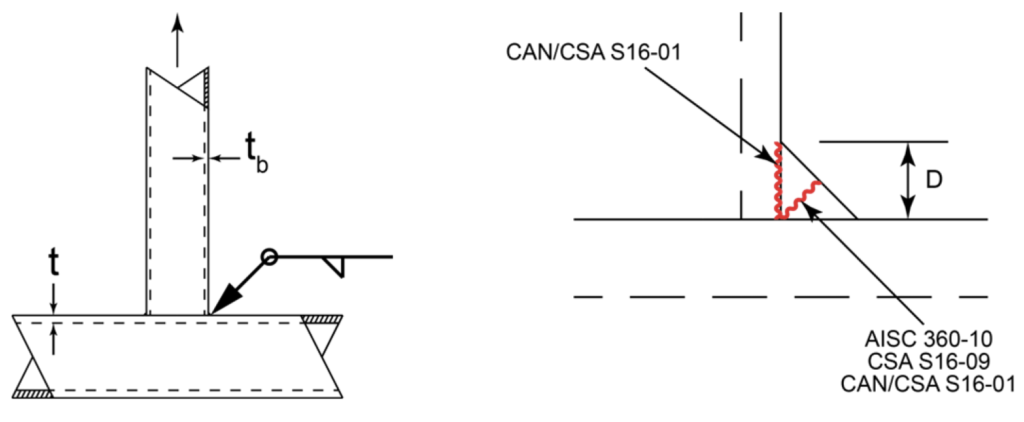

AISC 360 AISC 2010 has adopted Method ii in Section K Table K41 for welded connections to rectangular HSS by specifying various weld effective lengths l e for different connection types and loading situations. The minimum effective length of a fillet weld shall be at least four times the nominal size or the effective size of the weld shall be considered not to exceed 25 of its effective length. It also is anticipated that AWS D11 2008 will provide guidance on fatigue design of HSS welded connections using the Hot Spot Stress approach.

Provide information on the fatigue design of on-shore HSS welded connections most notably the draft international standard ISOWD 14347. When dealing with the exposed bearing structure hollow structural sections HSS are desired more than open sections. The gusset is welded to the HSS in the slot and the project- ing portion of the gusset is similar to the stem of the end tee connection.

In the mean time just wanted to add that Bentley has another connection design product called LIMCON which actually has HSS to HSS welded connections if. Welded Tee-to-HSS Connections. Built for connection design our proprietary software has undergone years of development and extensive peer review.

Welded HSS-to-HSS connections are typically used in trusses to connect branch members to main members with welds around the perimeter of the branch. Let me check with the product manager for RAM Connection on that. Local yielding of beam flange.

Welding Of Hollow Structural Sections Steel Tube Institute

Hss To Hss Connections Steel Tube Institute

Hss End Connection Welded From Three Sides Only Structural Engineering General Discussion Eng Tips

Stiffness Analysis W To Hss Moment Connection Idea Statica

Hss Welded To Hss Structural Engineering General Discussion Eng Tips

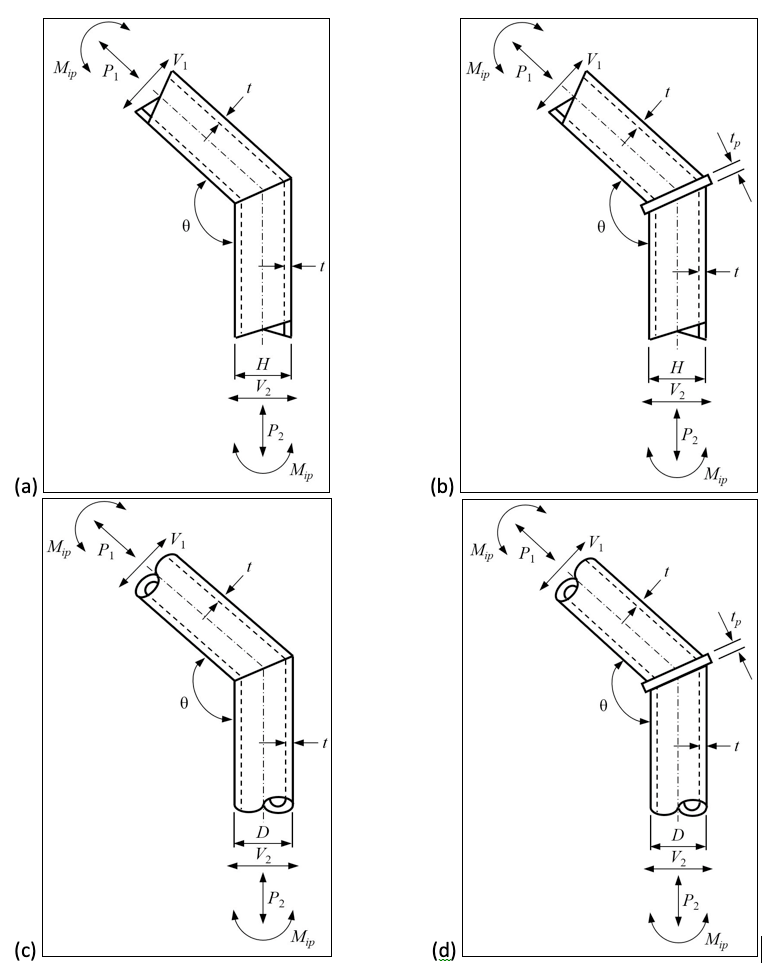

Hss Knee Connections Steel Tube Institute

Hss To Hss Welded Connection Side Matched Dimensions Structural Engineering General Discussion Eng Tips

0 comments

Post a Comment